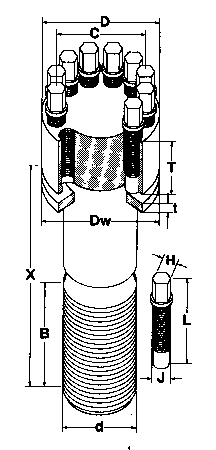

Pernos tensionadores mecánicos, serie SB12

Descripción

Perno de alta resistencia con pernos secundarios hexagonales.

Aplicación: Perno de alta resistencia usado mayormente en aplicaciones de grado 8; ideal para aplicaciones de temperaturas bajas.

Ficha Técnica

| Serie imperial | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Denominación | Rosca | Perno | Pernos secundarios | Arandela | Fuerza de apriete | Torque requerido | Peso | ||||||||

| d | D | T | C | L | X | B | Cant. | J | H | Dw | t | ||||

| - | " | mm | mm | mm | mm | mm | mm | - | " | " | mm | mm | libras | ft*lbs | kg |

| SB12-075-.../w | 3/4 | 34.3 | 17.8 | 25.4 | 76.2 | 38.1 | 31.8 | 4 | 1/4 | 3/16 | 34.3 | 3.3 | 20,400.0 | 14.0 | 0.3 |

| SB12-087-.../w | 7/8 | 37.6 | 17.8 | 28.7 | 76.2 | 44.5 | 31.8 | 6 | 1/4 | 3/16 | 37.6 | 3.3 | 30,600.0 | 14.0 | 0.4 |

| SB12-100-?/w | 1 | 43.9 | 22.9 | 33.3 | 101.6 | 50.8 | 38.6 | 6 | 5/16 | 1/4 | 43.9 | 4.1 | 48,600.0 | 27.0 | 0.7 |

| SB12-112-?/w | 1.1/8 | 47.0 | 22.9 | 36.6 | 101.6 | 57.2 | 38.6 | 6 | 5/16 | 1/4 | 47.0 | 4.1 | 48,600.0 | 27.0 | 0.8 |

| SB12-125-?/w | 1.1/4 | 50.3 | 22.9 | 39.6 | 127.0 | 63.5 | 38.6 | 8 | 5/16 | 1/4 | 50.3 | 4.1 | 64,800.0 | 27.0 | 1.2 |

| SB12-137-?/w | 1.3/8 | 56.6 | 27.9 | 44.5 | 152.4 | 69.9 | 46.5 | 6 | 3/8 | 5/16 | 56.6 | 5.1 | 73,800.0 | 49.0 | 1.7 |

| SB12-150-?/w | 1.1/2 | 59.7 | 27.9 | 47.8 | 152.4 | 76.2 | 46.5 | 8 | 3/8 | 5/16 | 59.7 | 5.1 | 98,400.0 | 49.0 | 2.0 |

| SB12-162-?/w | 1.5/8 | 62.7 | 27.9 | 50.8 | 152.4 | 82.6 | 46.5 | 8 | 3/8 | 5/16 | 62.7 | 5.1 | 98,400.0 | 49.0 | 2.3 |

| SB12-175-?/w | 1.3/4 | 69.3 | 35.6 | 55.6 | 152.4 | 88.9 | 56.9 | 8 | 7/16 | 3/8 | 69.3 | 6.4 | 129,600.0 | 75.0 | 2.9 |

| SB12-187-?/w | 1.7/8 | 75.7 | 38.1 | 60.5 | 152.4 | 95.3 | 59.7 | 8 | 1/2 | 7/16 | 75.7 | 6.4 | 175,200.0 | 114.0 | 3.4 |

| SB12-200-.../w | 2 | 81.3 | 38.1 | 63.5 | 203.2 | 101.6 | 59.7 | 8 | 1/2 | 7/16 | 81.3 | 6.4 | 175,200.0 | 114.0 | 4.8 |

| SB12-225-.../w | 2.1/4 | 87.6 | 40.6 | 69.9 | 203.2 | 114.3 | 59.7 | 8 | 1/2 | 7/16 | 87.6 | 6.4 | 175,200.0 | 114.0 | 6.1 |

| SB12-250-.../w | 2.1/2 | 100.3 | 45.7 | 79.5 | 203.2 | 127.0 | 74.9 | 8 | 5/8 | 9/16 | 100.3 | 7.9 | 285,600.0 | 233.0 | 7.8 |

| SB12-275-.../w | 2.3/4 | 106.7 | 55.9 | 85.9 | 254.0 | 139.7 | 83.8 | 8 | 5/8 | 9/16 | 106.7 | 7.9 | 285,600.0 | 233.0 | 11.8 |

| SB12-300-.../w | 3 | 113.0 | 55.9 | 92.2 | 304.8 | 152.4 | 83.8 | 12 | 5/8 | 9/16 | 113.0 | 7.9 | 428,400.0 | 233.0 | 15.2 |

| SB12-325-.../w | 3.1/4 | 125.7 | 59.7 | 101.6 | 304.8 | 165.1 | 92.2 | 12 | 5/8 | 9/16 | 125.7 | 9.7 | 428,400.0 | 233.0 | 18.7 |

| SB12-350-.../w | 3.1/2 | 132.1 | 59.7 | 108.0 | 304.8 | 177.8 | 92.2 | 16 | 5/8 | 9/16 | 132.1 | 9.7 | 571,200.0 | 233.0 | 21.3 |

| SB12-375-.../w | 3.3/4 | 144.8 | 68.6 | 117.6 | 381.0 | 190.5 | 101.6 | 16 | 5/8 | 9/16 | 144.8 | 11.2 | 571,200.0 | 233.0 | 30.1 |

| SB12-400-.../w | 4 | 149.9 | 68.6 | 124.0 | 381.0 | 203.2 | 101.6 | 18 | 5/8 | 9/16 | 149.9 | 11.2 | 642,600.0 | 233.0 | 34.0 |

| SB12-425-.../w | 4.1/4 | 163.8 | 81.3 | 133.4 | 381.0 | 215.9 | 119.4 | 16 | 3/4 | 5/8 | 163.8 | 12.7 | 806,400.0 | 390.0 | 40.9 |

| SB12-450-.../w | 4.1/2 | 170.2 | 81.3 | 139.7 | 457.2 | 228.6 | 119.4 | 16 | 3/4 | 5/8 | 170.2 | 12.7 | 806,400.0 | 390.0 | 51.4 |

| SB12-475-.../w | 4.3/4 | 176.5 | 81.3 | 146.1 | 457.2 | 241.3 | 119.4 | 18 | 3/4 | 5/8 | 176.5 | 12.7 | 907,200.0 | 390.0 | 56.6 |

| SB12-500-.../w | 5 | 189.2 | 101.6 | 155.7 | 508.0 | 254.0 | 144.8 | 20 | 3/4 | 5/8 | 189.2 | 14.2 | 1,100,800.0 | 390.0 | 73.2 |

| SB12-525-.../w | 5.1/4 | 195.6 | 101.6 | 162.1 | 609.6 | 266.7 | 144.8 | 22 | 3/4 | 5/8 | 195.6 | 14.2 | 1,108,800.0 | 390.0 | 90.6 |

| SB12-550-.../w | 5.1/2 | 201.9 | 101.6 | 168.4 | 609.6 | 279.4 | 144.8 | 22 | 3/4 | 5/8 | 201.9 | 14.2 | 1,108,800.0 | 390.0 | 98.9 |

| SB12-575-.../w | 5.3/4 | 208.3 | 101.6 | 174.8 | 609.6 | 292.1 | 144.8 | 24 | 3/4 | 5/8 | 208.3 | 14.2 | 1,209,600.0 | 390.0 | 107.2 |

| SB12-600-.../w | 6 | 214.6 | 101.6 | 181.1 | 609.6 | 304.8 | 144.8 | 24 | 3/4 | 5/8 | 214.6 | 14.2 | 1,209,600.0 | 390.0 | 115.9 |

| Serie milimétrica | |||||||||||||||

| Denominación | Rosca | Perno | Pernos secundarios | Arandela | Fuerza de apriete | Torque requerido | Peso | ||||||||

| d | D | T | C | L | X | B | Cant. | J | H | Dw | t | ||||

| - | " | mm | mm | mm | mm | mm | mm | - | " | " | mm | mm | libras | ft*lbs | kg |

| SB12-M20-.../w | M20 | 34.0 | 18.0 | 26.0 | 76.0 | 40.0 | 30.0 | 8 | 6.0 | 5.0 | 34.0 | 3.3 | 30,240.0 | 10.0 | 0.3 |

| SB12-M24-.../w | M24 | 43.0 | 24.0 | 32.0 | 102.0 | 48.0 | 40.0 | 6 | 8.0 | 6.0 | 43.0 | 4.1 | 43,650.0 | 24.0 | 0.7 |

| SB12-M27-.../w | M27 | 47.0 | 24.0 | 35.0 | 102.0 | 54.0 | 40.0 | 8 | 8.0 | 6.0 | 47.0 | 4.1 | 57,420.0 | 24.0 | 0.8 |

| SB12-M30-.../w | M30 | 50.0 | 24.0 | 38.0 | 127.0 | 60.0 | 40.0 | 10 | 8.0 | 6.0 | 50.0 | 4.1 | 70,200.0 | 23.0 | 1.1 |

| SB12-M33-.../w | M33 | 57.0 | 28.0 | 43.0 | 152.0 | 66.0 | 46.0 | 8 | 10.0 | 8.0 | 57.0 | 5.1 | 87,660.0 | 45.0 | 1.6 |

| SB12-M36-.../w | M36 | 59.0 | 28.0 | 46.0 | 152.0 | 72.0 | 46.0 | 10 | 10.0 | 8.0 | 59.0 | 5.1 | 102,960.0 | 43.0 | 1.8 |

| SB12-M39-.../w | M39 | 63.0 | 28.0 | 50.0 | 152.0 | 78.0 | 46.0 | 12 | 10.0 | 8.0 | 63.0 | 5.1 | 124,020.0 | 43.0 | 2.1 |

| SB12-M42-.../w | M42 | 66.0 | 28.0 | 52.0 | 152.0 | 84.0 | 46.0 | 12 | 10.0 | 8.0 | 66.0 | 5.1 | 141,120.0 | 49.0 | 2.4 |

| SB12-M45-.../w | M45 | 74.0 | 37.0 | 57.0 | 152.0 | 90.0 | 58.0 | 10 | 12.0 | 10.0 | 74.0 | 6.4 | 166,680.0 | 83.0 | 3.2 |

| SB12-M48-.../w | M48 | 75.0 | 37.0 | 60.0 | 203.0 | 96.0 | 58.0 | 10 | 12.0 | 10.0 | 75.0 | 6.4 | 187,380.0 | 93.0 | 4.2 |

| SB12-M52-.../w | M52 | 81.0 | 37.0 | 64.0 | 203.0 | 104.0 | 58.0 | 12 | 12.0 | 10.0 | 81.0 | 6.4 | 187,725.0 | 78.0 | 4.8 |

| SB12-M56-.../w | M56 | 85.0 | 37.0 | 68.0 | 203.0 | 112.0 | 58.0 | 12 | 12.0 | 10.0 | 85.0 | 6.4 | 216,525.0 | 90.0 | 5.7 |

| SB12-M60-.../w | M60 | 90.0 | 37.0 | 72.0 | 203.0 | 120.0 | 58.0 | 14 | 12.0 | 10.0 | 90.0 | 6.4 | 246,900.0 | 87.0 | 6.5 |

| SB12-M64-.../w | M64 | 100.0 | 46.0 | 80.0 | 254.0 | 128.0 | 75.0 | 10 | 16.0 | 14.0 | 100.0 | 8.0 | 286,800.0 | 187.0 | 9.1 |

| SB12-M72-.../w | M72 | 111.0 | 56.0 | 88.0 | 254.0 | 144.0 | 84.0 | 12 | 16.0 | 14.0 | 111.0 | 8.0 | 374,550.0 | 203.0 | 12.2 |

| SB12-M80-?/w | M80 | 119.0 | 56.0 | 96.0 | 305.0 | 160.0 | 84.0 | 14 | 16.0 | 14.0 | 119.0 | 8.0 | 473,925.0 | 220.0 | 17.0 |

| SB12-M90-.../w | M90 | 138.0 | 60.0 | 110.0 | 305.0 | 180.0 | 89.0 | 12 | 20.0 | 17.0 | 138.0 | 10.0 | 614,625.0 | 199.0 | 22.2 |

| SB12-M100-?/w | M100 | 145.0 | 69.0 | 120.0 | 381.0 | 200.0 | 98.0 | 14 | 20.0 | 17.0 | 145.0 | 10.0 | 773,250.0 | 214.0 | 32.2 |

| SB12-M110-?/w | M110 | 164.0 | 81.0 | 134.0 | 457.0 | 220.0 | 116.0 | 12 | 24.0 | 19.0 | 164.0 | 13.0 | 950,250.0 | 373.0 | 47.5 |

| SB12-M120-?/w | M120 | 177.0 | 81.0 | 144.0 | 457.0 | 240.0 | 116.0 | 14 | 24.0 | 19.0 | 177.0 | 13.0 | 1,145,250.0 | 385.0 | 56.2 |

| SB12-M140-?/w | M140 | 201.0 | 102.0 | 167.0 | 610.0 | 280.0 | 142.0 | 14 | 27.0 | 19.0 | 201.0 | 14.0 | 1,311,975.0 | 490.0 | 98.9 |

| SB12-M160-?/w | M160 | 221.0 | 102.0 | 187.0 | 610.0 | 320.0 | 142.0 | 16 | 27.0 | 19.0 | 221.0 | 14.0 | 1,722,525.0 | 562.0 | 126.8 |